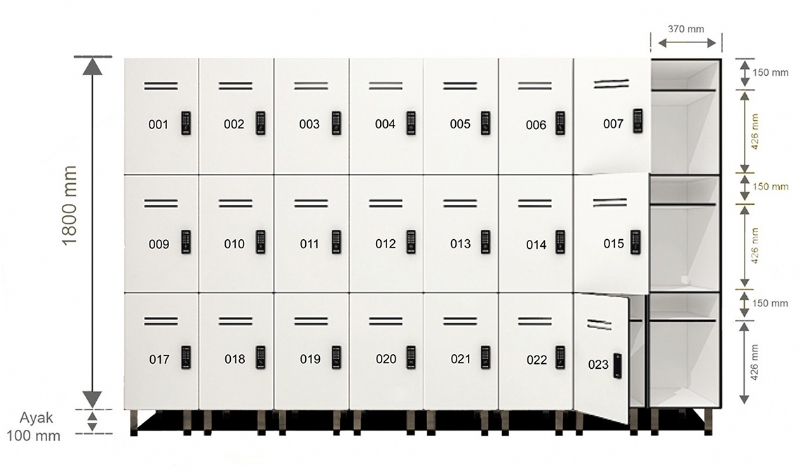

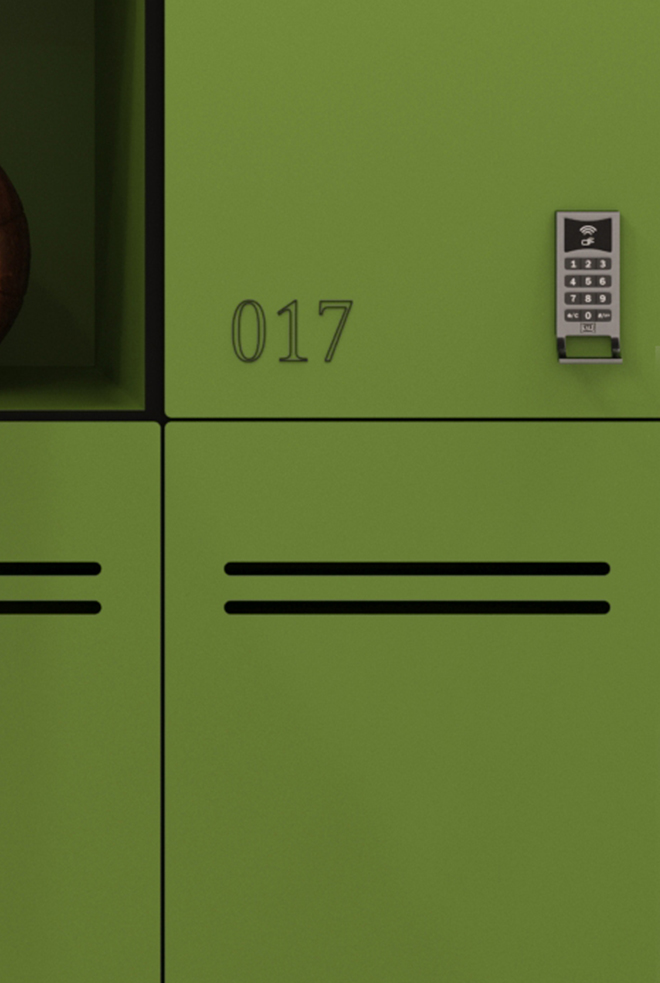

Three Door Locker is a compact laminate locker system developed for projects requiring higher storage density within limited spatial layouts. Its triple-compartment vertical segmentation increases user capacity while maintaining panel rigidity and door stability. High-pressure compact laminate panels provide resistance against humidity, impact, and cleaning chemicals. Durable hardware components ensure consistent operational performance in sports complexes, educational buildings, and high-traffic commercial environments.

You can download the necessary documents to seamlessly integrate our products into your projects from the link below.

You can download the necessary documents to seamlessly integrate our products into your projects from the link below.

LOCKER

LOCK

It comes with two folding keys. The ball-key construction makes it extremely tough to open.

LOCK

It comes with two folding keys. The ball-key construction makes it extremely tough to open.

LOCKER

NUMERATOR

It is produced in a standard size of 40 x 90 mm. It is attached to the mounting surface, which is drilled with CNC machines to fit its size.

NUMERATOR

It is produced in a standard size of 40 x 90 mm. It is attached to the mounting surface, which is drilled with CNC machines to fit its size.

LOCKER

HINGE

The thin construction of the hinge model, which protrudes just 3 mm from the surface, catches attention. Screw heads are not visible; only sharp lines, smooth surfaces, and rounded lines are seen.

HINGE

The thin construction of the hinge model, which protrudes just 3 mm from the surface, catches attention. Screw heads are not visible; only sharp lines, smooth surfaces, and rounded lines are seen.

LOCKER

GRILL

It was designed to provide air circulation on the locker cabinet doors. It is produced in standard size of 40x250 mm

GRILL

It was designed to provide air circulation on the locker cabinet doors. It is produced in standard size of 40x250 mm

Three Door Locker system is engineered for high-volume locker rooms where optimized space planning and durability are essential. The moisture-resistant compact laminate structure ensures long service life in demanding environments. Reinforced alignment detailing reduces deformation risk under intensive daily use. Modular production enables efficient installation and flexible integration into large-scale changing room projects.