Core N Panel Stock Colors (Download)

SANDER COMPACT CORE N and SANDER COMPACT CORE X panels,

are panel solutions classified within the compact laminate category, designed for use in wet areas and commercial environments. The visual, surface, and functional properties of the panels are equivalent to compact laminate panels commonly available in the market. Depending on the project usage scenario, CORE N is preferred for standard applications, while CORE X is specified for intensive and heavy-duty areas. Both panels are evaluated to operate in full integration with Sander system components.

In order to ensure system integrity and guarantee long-term performance, accessories compatible with the panel system are included. All connection elements, fixing screws, and accessories used within the system are designed and manufactured by Sander. This approach ensures complete compatibility between system components and secures long-term operational performance.

SANDER Compact Panel Systems CORE N - CORE X

Defining the Real Challenge in Wet Areas Correctly

Wet areas cannot be evaluated solely through aesthetic expectations in architectural projects. WC cubicles, changing areas, and shower cabins are exposed daily to high user circulation, continuous door opening–closing cycles, cleaning chemicals, fluctuating humidity levels, and in some cases direct water contact. For this reason, panel systems used in these environments should not only be assessed based on their initial appearance, but also on how they behave over time, how well they maintain their form, and how maintenance requirements are managed.

SANDER’s approach is built on differentiating wet areas according to usage conditions rather than treating them as a single uniform environment.

CORE N | WHY STANDARD?

Under standard usage conditions, CORE N:

Maintains dimensional stability over the long term.

Does not create misalignment in doors and panel joints.

Is compatible with daily cleaning and hygiene applications.

Especially in WC cubicles where user traffic is high, door opening–closing cycles are frequent, and cleaning intervals are intensive, CORE N provides consistent and predictable performance, creating a reliable reference point within projects.

THE CONSCIOUS LIMIT OF CORE N

Within the SANDER approach, each product has a clearly defined area of correct application. CORE N is not positioned for shower cabins where direct and continuous water contact exists.

This is not a weakness; rather, it represents a consciously defined technical limitation. When usage conditions exceed standard boundaries, a different solution is activated.

Shower cabins are among the most demanding areas within wet environments. Continuous water exposure, high humidity, and mechanical stress move these areas beyond standard applications. At this point, SANDER COMPACT CORE X becomes the complementary part of the system.

CORE X:

Provides enhanced resistance on surfaces exposed to continuous water contact.

Offers additional performance in areas where durability expectations increase.

Adds performance and safety margin in applications where mechanical stress intensifies.

THE CORRECT INTERPRETATION OF CORE X

CORE X is not an alternative to CORE N.

CORE X is a complementary solution that becomes active only when standard boundaries are exceeded.

Through this approach:

Unnecessary cost increases are avoided.

Higher performance is used only where needed.

Project budgets are balanced based on technical justification.

SANDER APPROACH | Not a Product, but a System

SANDER does not evaluate compact panel solutions as a standalone “panel product.” The panel is assessed as part of a complete system including hinges, locks, legs, connection profiles, and installation detailing.

Through this system approach:

Mechanical loads on the panel are evenly distributed.

Alignment issues that may occur over time at door and panel joints are minimized.

Stable and predictable long-term usage performance is achieved.

This perspective reduces technical risks that may arise during and after installation, while also controlling operational and maintenance costs.

THE CONCEPT OF STANDARD PANEL | POSITIONING OF CORE N

Every architectural project requires a standard panel solution that simplifies design and implementation processes, minimizes risks, and avoids unexpected issues on site.

SANDER COMPACT CORE N directly responds to this requirement.

CORE N is positioned as the primary panel solution safely used in the majority of projects, based on SANDER’s long-term field experience.

MATERIAL REFERENCE

Panels with high-density fiber structure (>1050 kg/m³) are accepted as reference in terms of dimensional stability and mechanical durability in humid environments.

SANDER’s panel approach considers the panel not merely as a surface, but as a functional usage component.

SYSTEM INTEGRITY

Panel performance is not meaningful when evaluated independently from hinges, locks, legs, and connection profiles.

In SANDER systems, all components are:

Fully compatible with the panel.

Designed to balance load distribution.

Engineered as an integrated whole that supports long-term stability.

CONCLUSION | Clear Architectural Decision Framework

Within the SANDER panel approach, the decision mechanism is clear:

CORE N is the standard and reliable primary solution for the majority of architectural projects.

CORE X is the complementary option activated in shower cabins and special conditions where the standard is not sufficient.

References and Technical Sources of Inspiration

While positioning SANDER Compact Core N panel technically and defining its usage boundaries, performance criteria internationally defined for compact laminate product groups and technical evaluations for wet area applications were taken as reference.

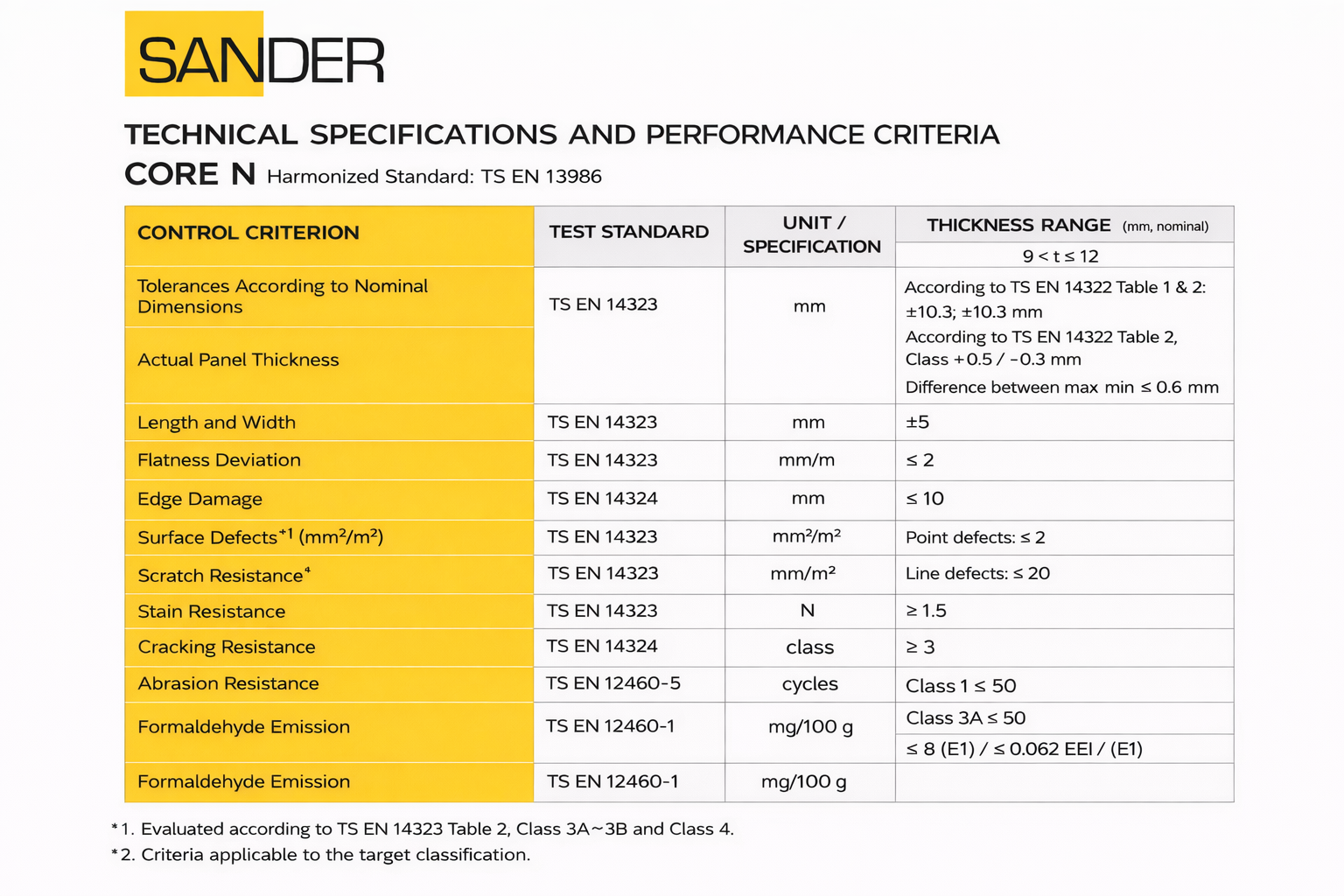

Within this framework, performance expectations defined under the TS EN 438 (Core X Compact Laminate) standard regarding dimensional stability, surface durability, chemical resistance, and emission values were evaluated according to the intended usage scenario of the product. Compact Core N panel has been designed specifically considering humid indoor conditions anticipated for publicly used WC cubicle and locker applications.

During the technical evaluation process, panel thickness and tolerance values were assessed to provide long-term stability in humid indoor environments, while surface characteristics were shaped based on resistance to cleaning chemicals, scratching, and staining. Formaldehyde emission values were also controlled in accordance with healthy indoor usage requirements.

In line with this approach, Compact Core N panel is evaluated for safe use in indoor WC cubicle applications such as shopping malls, schools, offices, hospitals, and similar facilities.

The usage boundaries of the product are defined with the same technical transparency. Compact Core N panel is not designed for applications exposed to continuous and direct water pressure. Therefore, shower cabins and applications involving constant water contact should be evaluated outside the scope of this product.

This technical limitation does not stem from material quality, but from engineering and performance criteria defined according to the intended usage scenario. The SANDER approach positions products not only through technical values, but through correct usage definition and clearly defined performance expectations.

Technical Specifications and Performance Criteria

SANDER Projects: CORE N as the Standard

CORE X Applied Only Under Special Conditions