NEDEN ![san exclusive]() Ürünleri

Ürünleri

Çeyrek Asırlık Tecrübeyle Güvenilir Mimari Çözümler

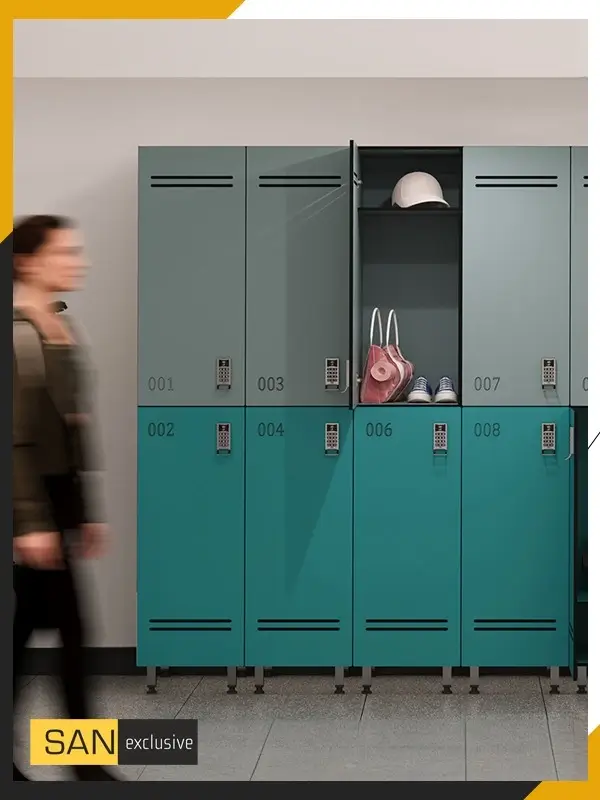

SANDER®️, 2001 yılından bu yana kompakt laminat WC kabin ve soyunma dolabı sistemleri üreten bir üretici markadır. Islak hacim uygulamalarında tasarım kararlarını üretim disipliniyle birleştiren entegre bir yapıya sahiptir. Kurumsal yaklaşımımız, projeye yalnızca ürün yerleştirmek üzerine değil; mekânın kullanım yoğunluğunu, bakım senaryosunu ve uzun vadeli performansını birlikte değerlendirmek üzerine kuruludur. Bu nedenle WC kabin ve kompakt laminat sistemlerimiz, proje metrajı doğrulandıktan sonra planlı üretim organizasyonu içinde hazırlanır ve saha koşulları dikkate alınarak uygulanır.Soyunma dolabı çözümlerimiz; spor tesisleri, eğitim yapıları, sanayi alanları ve ticari projelerde farklı kullanım senaryolarına göre yapılandırılır. Amaç, yalnızca estetik bir çözüm değil yıllar boyunca stabil kalacak bir sistem kurmaktır. SANDER®️, üretimden montaja kadar süreci kendi organizasyonu içinde yöneten bir yapıya sahiptir. Bu yaklaşım, büyük metrajlı projelerde teslim sürekliliği ve teknik güven sağlar. Yurt içi ve yurt dışı uygulamalarda edindiğimiz deneyim, markamızın kurumsal istikrarını ve planlı üretim kültürünü desteklemektedir.